The tire is one of the oldest inventions of humankind. However, in the age of mass production, it is understandable that we don’t know how certain things are made. In this article, we are going to talk about how our car tires are manufactured.

By learning a bit about tires, you can understand the part of your vehicle that gives it the ability to move. This is true for many different types of vehicles, which is why the tire market is blossoming. Almost everyone needs tires in some shape or form.

Let’s delve a bit into this topic and understand how something like a rubber compound can turn into a tire with a detailed tread!

The Secrets of Tire Manufacturing

The typical tire factory has various equipment and machinery to utilize. Tires have to be carefully designed, molded, constructed to properly support the vehicle. The bottom of the tire has to say flat even during sharp cornering, while its sidewall has to resist flexion.

It has to be solid construction, in the end, otherwise, it wouldn’t even meet the standards for wide distribution. Yes, a tire looks simple enough at first sight, but what about all those lines on top of car tires, both circumferential and lateral?

Instead of confusing you with more of these questions, we are going to pull the brakes for a second. In order to understand the whole tire manufacturing process, you need to start with the basics. It all starts with some rubber compounds.

Compounded Materials

First, the rubber compounds need to go through a mixing process. The compounded materials form a blend that makes up the tire. Depending on what type of tire they want, tire manufacturers add hard or soft materials in the mixing process.

They use harder rubber compounds if they aim for a more durable tire. Another benefit of higher durability is that it ensures better fuel economy. Sturdier, stronger tires have a lower rolling resistance, meaning that they require less energy (fuel) to get them rolling.

Harder compounds are also used in the manufacturing process of commercial tires. Vehicles like large trucks and buses need to withstand heavy loads and it enables them to do so.

Softer compounds are also widely used in tire production, but rather for tires that require more grip, especially at high speeds. The rubber compound mix can widely differ from one brand to the other, although they all use the same basic components. These include wire, carbon black, fabric, rubber, and chemical compounds.

Natural Rubber

Natural rubber is one of the ingredients tires are made of. It strengthens the tire’s structure, extending its service life by preventing it from wearing and tearing. This is also the ingredient that keeps the tire intact, preventing the sidewall from cracking under pressure.

Synthetic Rubber

Natural and synthetic rubber compounds are mixed together as raw materials. Then they combine the synthetic rubber with other tire components such as butadiene and styrene-butadiene. Both of these are rubber polymers have their own properties. They determine most of the tire’s performance characteristics.

Silica is by far the most used synthetic rubber in the industry. Read more about its use and why it is important in tire production.

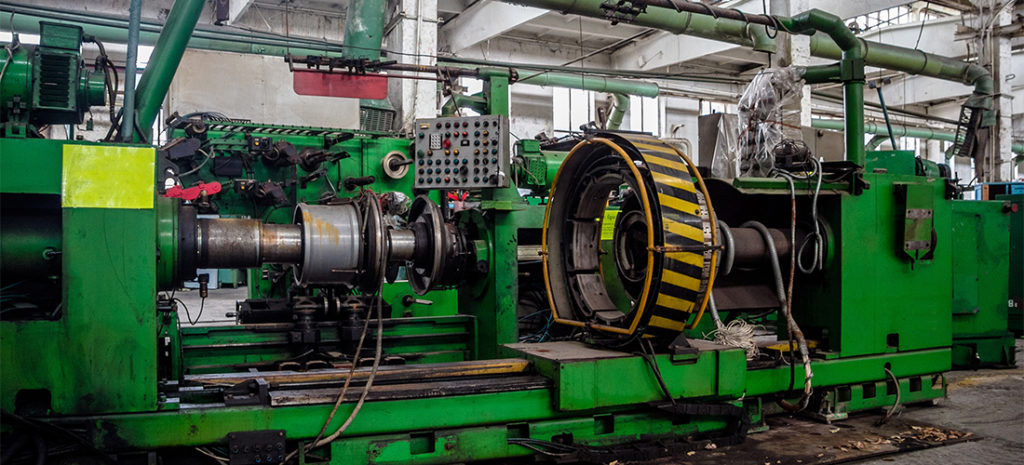

Tire Building Machine

Today, tire manufacturing uses high-tech tire building machines (TBM). This greatly increases the number of tires that manufacturers can produce in a short amount of time. To simplify things in most tire factories, they minimize the overall complexity of machine maintenance and set-up times.

One person can handle multiple computer systems while the TBM takes care of the hard work. It grabs the sidewall, inner liner, body ply, tread, bead, and cord body and uses them to put a tire together on the assembly line. The tire that comes out is a “green tire”, which only means that it is unfinished and still has to go through the curing process.

Step By Step of Tire Manufacturing

To make tires, brands need raw materials, such as a combination of natural and synthetic rubber. But how do we get from the raw rubber to the new tire through the tire production process? Brands manufactured passenger tires, pneumatic tires, light truck tires, or any typical radial tire by following similar steps.

The main steps are pretty much the same, the difference is in the rubber compound mix and the equipment used during those steps. After accepting a tire design, the factory also needs to develop new equipment that is tailored to the new model. If the brand wants a tire with different performance characteristics, they need to combine together a variety of materials.

Complications can easily arise, which is why the tire making industry is an art of its own. Below, we are going to introduce you to the steps that characterize pretty much every tire making process today.

Step-by-step of tire making:

- Rubber Compounds

- Construction

- Assembly

- Molding

- Inspection

Step One – Rubber and Other Ingredients:

The first step when it comes to tire making is to get some high-quality ingredients. Anyone who wants to start making tires has to invest in raw materials first. Besides rubber, you are going to need some steel, some chemicals, and textiles as well.

Various branches supply these raw branches in the industry, as brands later use them to create tire parts. The need for steel as a starting material is high, as it is the essential material for steel belts and bead cores. Manufacturers make steel belts of steel cord, while the bead core uses steel wires.

There are chemicals needed too in order to produce silica or any other synthetic variant. This is in use in order to increase grip and extend service life for tires. In its natural form, workers extract rubber from trees in the form of liquid latex. They extract coagulates of latex with acid and then transport the raw rubber in bales.

Textiles are also needed for textile reinforcement cables and rubber-covered fabric plies. The materials used are nylon, aramid fibers, rayon, and polyester. Manufacturers utilize them for reinforcement that strengthens the tire structure and adds puncture resistance.

Step Two – Construction:

They take the bales of natural and synthetic components and cut them into the precise portions needed for the manufacturing process. Then they mix it with other ingredients depending on the desired characteristics. The resulting mixes can vary, as most passenger tires use an average of twelve different rubber compounds.

The making of a new tire usually starts with pre-treated steel cords. They embed these in one or two layers of rubber. Then they cut it at an angle and make sure that its length is in accordance with the desired tire size.

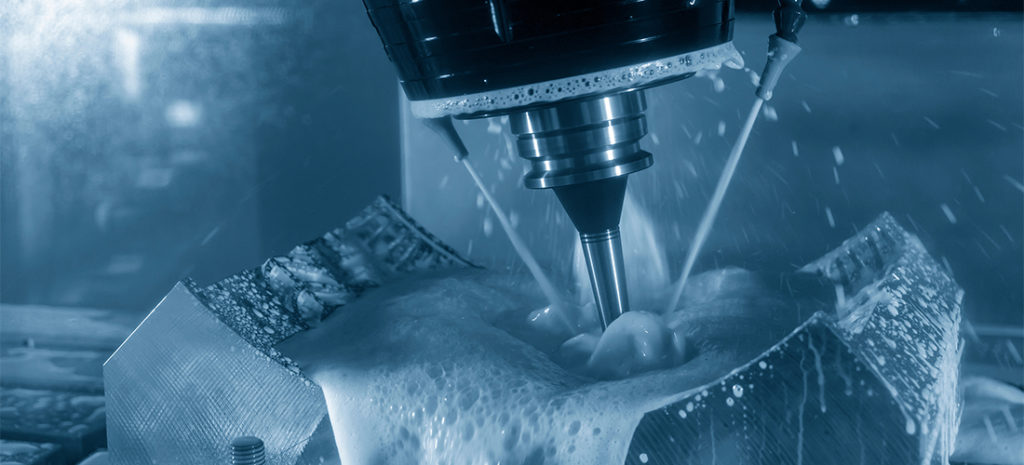

Then they take the rubber material out of the mixer in a kneadable form. They put it in a screw-type tool that produces extruded rubber layers, which are like strips of tire tread. After checking its weight per meter, they cool it down a bit and cut it to length to fit the tire size.

The next procedure is embedding the textile treads in a layer of rubber using a huge roller device. The sheet that comes out is cut in the direction of travel at a 90-degree angle to get the desired width. The steel bead consists of ring-shaped steel wires coated in rubber. Once it’s ready, they use a rubber apex to fit the loop.

Each sidewall section is cut to fit the tire design, and then they turn it out using an extruder. The last part is the airtight inner liner, which is formed into a wide, thin layer using a calendar.

Step Three – Assembly:

The robotized tire building machine (TBM) is the tire assembler that handles the different pre-manufactured parts. These include the inner liner, sidewall, tread, bead, casing ply and cord body. The goal of the TBM is to manufacture one green tire after the other using different tire components.

The tire assembler starts building the tire using its machine drum. It takes the inner liner, wraps it around the drum, and wraps the first body ply on top. Then comes the second ply, after which the bead assemblies get in position and the machine drum inflates a bladder that forces the body plies against the bead assemblies.

The next step is pressing the sidewall rubber parts onto both sides. Then they hand the green tire over to another machine that continues the assembly. It adds the belts, the nylon cap, and the raw tread rubber on top. At this point, the tire still has to go through the so-called curing process because that’s when it gets its tread pattern.

Step Four – Molding:

This is the step of the tire building process where they apply both heat and pressure to the tire. For this, it has to be put in a mold that is going to shape the tire according to the initial design. Raising the pressure in the tire makes sure it presses its tread and sidewall into the mold.

As a result, the molding process creates the green tire with both the tread pattern and the sidewall lettering. After the process, they relieve the internal pressure and the result is a cured tire. The final move here is to place the tire on a post-cure inflator (PCI). It inflates the tire and lets the air-filled inner tube and the outer parts cool down a bit.

Step Five – Inspection:

In fact, tires go through quality control during every individual stage of their production. The tread design and the internal components including the tire tube and the tire plies are closely examined throughout the manufacturing process.

There are three main quality checking methods that are recommended by the tire manufacturers association. These include X-raying, visual inspection, and a range of tire uniformity checks. Tires need to go through these inspections and check before the manufacturer can send them to the warehouse.

Frequently Asked Questions (FAQs):

Are tires made from oil?

Modern tire technology blends consist of about 24 percent of synthetic rubber and 19 percent of natural rubber. The main raw material for the synthetic variant is crude oil. Although it is one of the main ingredients in tire manufacturing, oil is definitely not enough.

What are tires actually made from?

Tire brands use other components such as styrene-butadiene and butadiene together with synthetic rubber. The natural option is the rubber tree (Hevea Brasiliensis) available for natural production. In the typical tire making process, metal, wire, and other materials are also used.